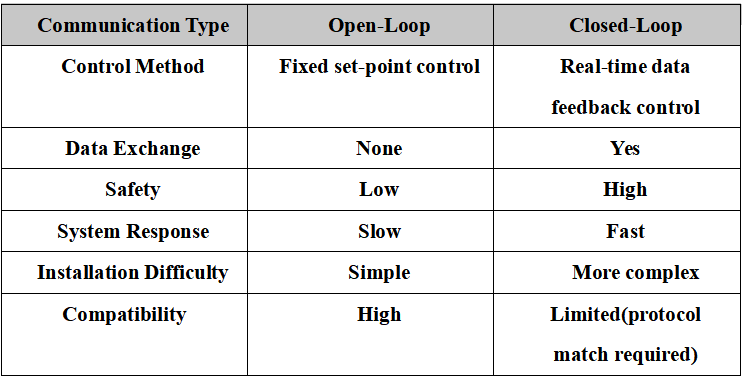

III. Comparison and Summary

Ⅳ. Recommended Application Scenarios

Title

Related Products